Shipping teams spend a lot of time applying paperwork and labels. The label over label method cuts those steps down by combining a packing slip label and a shipping label into one application. One motion. Fewer pauses on the line. Less room for error.

What Is “Label Over Label” in Shipping and Fulfillment?

Label over label is a shipping method where a packing list label sits underneath a shipping label, and both layers are applied to a package at the same time. It replaces the workflow built around:

- Folded 8.5×11 packing slips

- Plastic pouches

- Manual printing, folding, inserting, and sticking

- Separate label application at the pack station

With label over label, the steps collapse into one. The packing list is the base layer. The shipping label sits on top. The printer or applicator places them together in a clean, repeatable motion that works across high-volume operations.

Common use cases:

- E-commerce distribution centers

- Subscription box operations

- At- home medical test kits

- High-volume consumer goods fulfillment

- Conveyor-driven shipping lines

- and more!

The process stays fast. The presentation looks better. And your team spends less time fixing preventable mistakes.

Why “Label Over Label” Matters in E-Commerce Fulfillment

If you ship direct-to-consumer, you already know where the bottlenecks are. Labeling is one of them. A label over label system removes several friction points at once.

Key advantages for online retailers:

- Apply the shipping label and packing slip label at once

- Support e-commerce automation without adding steps

- Produce clean, consistent packages

- Add inserts (coupons, return labels, gift and thank-you messages, loyalty offers) without extra labor

Key Automation Benefits of Label Over Label Systems

When viewed through Lean and Six Sigma principles, the benefits are clear. You’re getting rid of extra movement, extra print cycles, and extra chances for variation.

How label-over-label strengthens a lean shipping process:

- Increases throughput by removing extra labeling steps

- Reduces mislabels because the two layers move as one

- Improves consistency across shifts, teams, and equipment

- Cuts non-value-added tasks from the outbound workflow

If your operation is pushing for shipping process efficiency, this method eliminates the small delays that steal hours from busy lines.

Inside the Multiplex System from Chicago Tag & Label

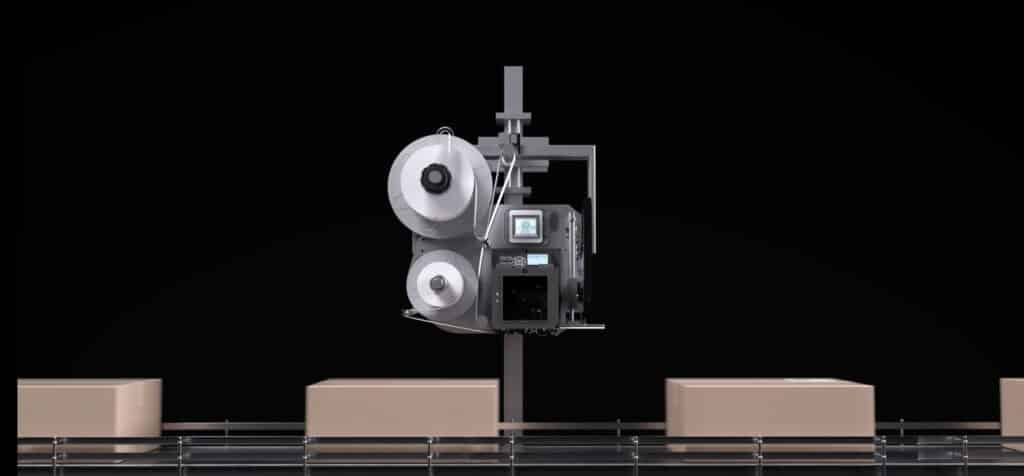

Other label-over-label setups rely on two applicators. One for the packing slip. One for the shipping label. The Multiplex system applies both layers with a single printer or applicator.

What this means for your operation:

- Standard equipment

- Fewer machines

- Less maintenance and down-time

- Faster application

- Lower capital costs and less floor space

- A simpler workflow your team won’t fight with

Multiplex can also apply coupons, return labels and instructions, gift messages, warranty information, Prop 65 or other custom inserts without slowing your process.

Explore Chicago Tag & Label’s related solutions.

- Custom enclosed packing list labels

- Automatically applied labels

- Manually applied labels

- Enclosed packing list solutions

Applications Beyond Packing Slips

Label-over-label systems aren’t limited to shipping paperwork. The layered format gives you room to add content without adding labor, which makes it useful outside the usual pack-station workflow.

You can use the underlayer for:

- Coupons or promotional offers

- Gift messages or holiday inserts

- Loyalty program codes

- Product registration instructions

This frees marketing teams to personalize the customer experience without slowing down fulfillment. And for operations managers, it means no new steps, no new equipment, and no extra handling. One application. More value in every parcel.

Is Label Over Label Right for Your Operation?

The method delivers its strongest ROI in operations where speed and consistency matter. If any of the points below fit your environment, label over label is worth a closer look:

- High daily shipping volume

- Repetitive pack workflows

- Frequent picking or labeling errors

- Labor shortages at pack stations

- Pressure to improve throughput without adding headcount

- Too many touchpoints between picking, packing, and labeling

In those scenarios, the time you save per package adds up fast. Fewer machines, fewer manual steps, and fewer mistakes all lead to stronger margins and smoother peak-season performance.

Lean into Automation: Why Now’s the Time

Many operations are dealing with the same pressures. Labor is tight. Order volume keeps rising. Customer expectations keep shifting. And the cost of getting a label wrong has never been higher. Automation isn’t something to put off for another quarter. It’s the safest way to stabilize throughput and protect accuracy when everything around you is moving faster.

Label over label fits this reality. It removes wasted motion, simplifies the application process, and gives your team a cleaner workflow to manage. It also scales easily as your shipping volume grows, which keeps you from having to rebuild your process every peak season.

When you’re ready for a system that stays fast, consistent, and controlled, Chicago Tag & Label has the tools and experience to support it. Talk with us today to learn more!

Label Over Label Packing Slip FAQs

What is a packing slip label?

A packing slip label is a label that carries the order details normally printed on an 8.5×11 sheet. Instead of using a pouch and loose paper, the information is built into a label that applies cleanly to the box. It keeps the process fast, consistent, and easier to automate.

How does a “label over label” system work?

A label over label system applies two layers at once. The packing slip label sits underneath. The shipping label goes on top. One motion applies both, which improves shipping process efficiency and helps reduce shipping errors across high-volume lines.

What’s the difference between Multiplex and other layered label systems?

Other systems need two applicators or specialized printers to handle the two layers. Multiplex uses one standard printer. That cuts maintenance, frees up space on the line, and supports higher fulfillment label automation. It also keeps the placement consistent, which makes it easier to run a lean shipping process.

Can I use label-over-label for promotional inserts?

Yes. The underlayer can hold coupons, messages, loyalty codes, or other inserts without adding labor. You get marketing value without slowing down packing stations or disrupting e-commerce automation.

Is “label over label” compatible with automatic label applicators?

Yes. The method was built for automation. It works on high-speed conveyor lines and integrates easily with automatic applicators, making it a strong fit for packing list automation in e-commerce and distribution centers.

How does it support Six Sigma or Lean warehouse practices?

It removes extra steps. It reduces variation. And it gives you one controlled action instead of multiple manual touches. That’s why label-over-label pairs well with Lean and Six Sigma: fewer delays, less motion, and a clear way to reduce shipping errors at scale.